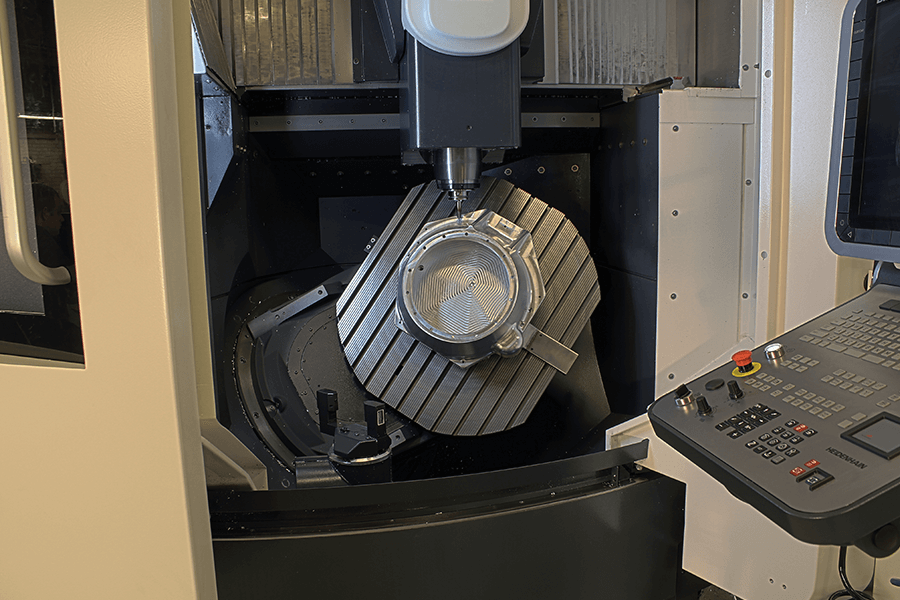

CNC Machining in Aluminium and Magnesium

With over 20 advanced CNC machining centers, we utilize cutting-edge equipment to deliver high-quality machined components in aluminum and magnesium.

We specialize in managing small to medium-sized quantities, with a setup optimized for prompt delivery while maintaining the highest quality standards.

Overview of Our Machining Department

- 20 state-of-the-art machining centers

- 4000 m² climate-controlled production space

- 3-axis and 5-axis milling and turning

- Automated solutions for unmanned operations

- In-house measuring and documentation capabilities

Defence projects

Formkon is a member of the DI Danish Defence and Security Industries Association and has been supporting the industry with aluminium and magnesium components for decades. We offer full traceability in component manufacturing and also handle advanced surface treatment requirements.

Our Machines - Components in Aluminium and Magnesium

| 5-AXIS CNC MACHINING | ||

| Produzent | Modell | Arbeitsbereich |

| Hermle | C650U | 1050x900x600 mm |

| Hermle | C42 with Kuka Robot | 800x800x550 mm |

| Hermle | C42 with Kuka Robot | 800x800x550 mm |

| Hermle | C42 | 800x800x550 mm |

| Hermle | C22 | 450x600x330 mm |

| Hermle | C400 | 850x700x500 mm |

| Deckel Maho | DMU 80evo | 800x650x550 mm |

| Deckel Maho | DMU 60evo | 650x450x450 mm |

| Deckel Maho | DMU 60monoblock | 630x560x560 mm |

| Deckel Maho | DMU 60monoblock | 630x560x560 mm |

| 3-AXIS CNC MACHINING | ||

| Hermle | C400V | 850x700x500 mm |

| Deckel Maho | DMC 75V line | 750x600x550 mm |

| Deckel Maho | DMC 100V | 1000x800x650 mm |

| Deckel Maho | DMC 50V | 500x400x400 mm |

| Deckel Maho | DMU65 Monoblock | 735x650x560 mm |

| TURNING | ||

| Mazak | I200-S mit Roboter | Ø650×1000 mm |

| DMG MORI | NLX2500 / 700 | Ø460×1255 mm |

| Gildemeister | CTX 510 | Ø600×1000 mm |

| Gildemeister | CTX 420Y linear | Ø450×650 mm |

| 3D COORDINATE MEASURING MACHINES | ||

| Wenzel | LH108 | 2000x1000x800mm |

| Wenzel | LH87 | 1500x800x700mm |

| Wenzel | LH87 | 1500x800x700mm |

CNC Machining - Our Competences in Brief

CNC milling

Our 3-axis and 5-axis CNC milling machines form the core of the department. Their high level of precision and flexibility allow us to handle complex components in aluminium and magnesium where the customers have very high demands for tolerances, surface finish, etc.

Our primary production consists of small to medium-sized quantities. Our machines are connected to MasterCam where all programs are made. The most recent investments have been made in automation, such as pallet exchanger, robot solutions and large tool hoppers. This allows us to run many unmanned hours.

.

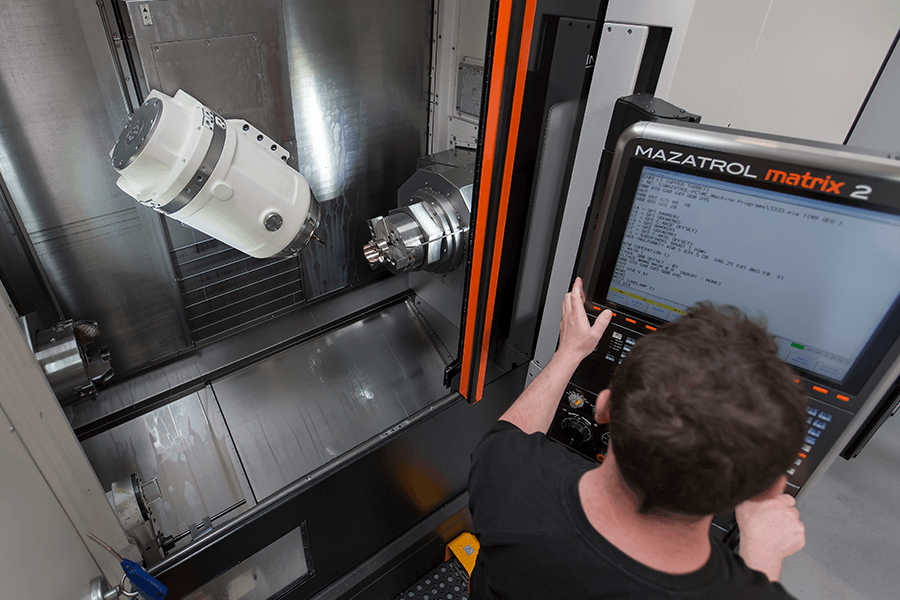

CNC turning

This department consists of 3 Gildemeister lathes with Heidenhein Plus IT control and 1 Mazak multitasking machine. Jobs can be moved fluently between the machines as they are all connected to MasterCam where all programs are made. This minimises the risk of errors and reduces setup times for new and repeat orders.

The 3 Gildemeister machines have rotating tools and one machine also has a Y-axis. Mazak Integrex has a full 5-axis head and a large tool hopper. The machines allow items up to Ø650mm in all materials.

.

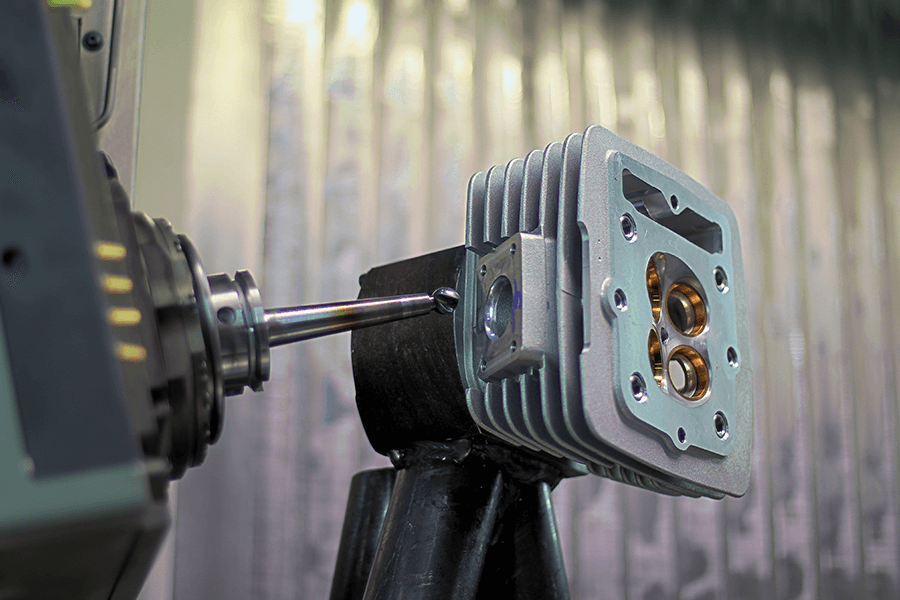

CNC Post-Machining of Castings

We have many years of experience in Post-Machining of cast components in aluminium and magnesium. We mainly finish prototypes and small series. Our setup for finishing cast items has been optimised for this.

To ensure the best possible result, all of our precision machines are fitted with probes to allow probing of all cast items to find the best fit before initiating the CNC machining process.

Measuring and documentation

After CNC machining, we can measure and document the components to ensure they meet the highest quality standards